Functions and Roles of Electro Fusion Repair Saddle

The Electro Fusion Repair Saddle is a specialized fitting used in HDPE piping systems, designed to repair localized leaks or damages quickly, effectively, and durably. This product plays a crucial role in maintaining the stability and safety of entire piping networks, whether for clean water, wastewater, gas, or chemical transport—especially in modern infrastructure, industrial, urban, and agricultural projects.

Functions and Roles of Electro Fusion Repair Saddle

The Electro Fusion Repair Saddle is a specialized fitting used in HDPE piping systems, designed to repair localized leaks or damages quickly, effectively, and durably. This product plays a crucial role in maintaining the stability and safety of entire piping networks, whether for clean water, wastewater, gas, or chemical transport—especially in modern infrastructure, industrial, urban, and agricultural projects.

1. Electro Fusion Technology – Modern Electric Heat Welding

This fitting utilizes Electro Fusion technology, where built-in metal coils (typically copper) are embedded within the saddle body. When connected to a power source, the coils heat up and melt the polypropylene (PP) material of both the saddle and the HDPE pipe surface.

This controlled heating process:

-

Creates a strong, homogeneous joint.

-

Ensures 100% leak-free connection.

-

Requires no adhesives, solvents, or sealants like traditional methods.

-

Is suitable for high-pressure systems (PN10–PN16).

2. Fast and Effective Repairs

The Electro Fusion Repair Saddle allows localized repairs to be made without dismantling or replacing the entire pipe segment, helping to:

-

Save material and labor costs.

-

Shorten repair time and reduce downtime.

-

Minimize risks when performing maintenance on active systems.

The saddle is placed directly over the damaged area, then fused using an electro fusion welding machine. This process is safe, clean, and practical, even in complex environments like underground, confined spaces, or wet areas.

3. Versatility and Wide Application

Besides repairing, the Electro Fusion Saddle can also be used to:

-

Create branch connections from the main pipeline without disassembly.

-

Install auxiliary devices (such as valves or flow meters) through the built-in outlet.

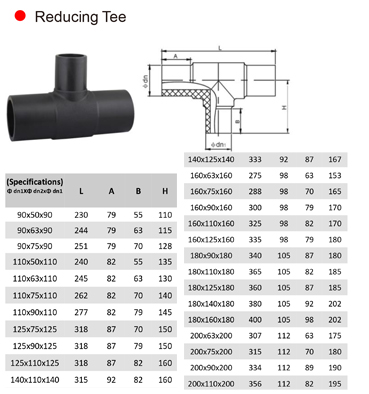

Available in sizes from DN90 to DN315, the product suits a wide range of uses—from residential and agricultural to heavy industrial systems.

4. Key Advantages

-

High pressure resistance and long-term durability.

-

Resistant to corrosion, chemicals, UV, and harsh environments.

-

Strong, vibration-resistant joints that don’t break or leak.

-

Average lifespan of up to 50 years when installed properly.

-

Complies with international standards: BS 5114, AS 4020.

5. Real-World Applications

-

Urban and rural water supply systems.

-

Wastewater treatment and drainage networks.

-

Gas transmission systems.

-

Food and beverage processing plants.

-

High-tech agriculture (drip and sprinkler irrigation).

-

Mining and petroleum industries.

Conclusion:

The Electro Fusion Repair Saddle is a high-tech, smart, and economical solution for repairing damaged HDPE pipes without affecting the entire system. It ensures continuous operation, reduces technical risks, extends pipeline life, and makes maintenance more convenient than ever.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Functions and Roles of Electro Fusion Repair Saddle

The Electro Fusion Repair Saddle is a specialized fitting used in HDPE piping systems, designed to repair localized leaks or damages quickly, effectively, and durably. This product plays a crucial role in maintaining the stability and safety of entire piping networks, whether for clean water, wastewater, gas, or chemical transport—especially in modern infrastructure, industrial, urban, and agricultural projects.

Functions and Roles of Electro Fusion Repair Saddle

The Electro Fusion Repair Saddle is a specialized fitting used in HDPE piping systems, designed to repair localized leaks or damages quickly, effectively, and durably. This product plays a crucial role in maintaining the stability and safety of entire piping networks, whether for clean water, wastewater, gas, or chemical transport—especially in modern infrastructure, industrial, urban, and agricultural projects.

1. Electro Fusion Technology – Modern Electric Heat Welding

This fitting utilizes Electro Fusion technology, where built-in metal coils (typically copper) are embedded within the saddle body. When connected to a power source, the coils heat up and melt the polypropylene (PP) material of both the saddle and the HDPE pipe surface.

This controlled heating process:

-

Creates a strong, homogeneous joint.

-

Ensures 100% leak-free connection.

-

Requires no adhesives, solvents, or sealants like traditional methods.

-

Is suitable for high-pressure systems (PN10–PN16).

2. Fast and Effective Repairs

The Electro Fusion Repair Saddle allows localized repairs to be made without dismantling or replacing the entire pipe segment, helping to:

-

Save material and labor costs.

-

Shorten repair time and reduce downtime.

-

Minimize risks when performing maintenance on active systems.

The saddle is placed directly over the damaged area, then fused using an electro fusion welding machine. This process is safe, clean, and practical, even in complex environments like underground, confined spaces, or wet areas.

3. Versatility and Wide Application

Besides repairing, the Electro Fusion Saddle can also be used to:

-

Create branch connections from the main pipeline without disassembly.

-

Install auxiliary devices (such as valves or flow meters) through the built-in outlet.

Available in sizes from DN90 to DN315, the product suits a wide range of uses—from residential and agricultural to heavy industrial systems.

4. Key Advantages

-

High pressure resistance and long-term durability.

-

Resistant to corrosion, chemicals, UV, and harsh environments.

-

Strong, vibration-resistant joints that don’t break or leak.

-

Average lifespan of up to 50 years when installed properly.

-

Complies with international standards: BS 5114, AS 4020.

5. Real-World Applications

-

Urban and rural water supply systems.

-

Wastewater treatment and drainage networks.

-

Gas transmission systems.

-

Food and beverage processing plants.

-

High-tech agriculture (drip and sprinkler irrigation).

-

Mining and petroleum industries.

Conclusion:

The Electro Fusion Repair Saddle is a high-tech, smart, and economical solution for repairing damaged HDPE pipes without affecting the entire system. It ensures continuous operation, reduces technical risks, extends pipeline life, and makes maintenance more convenient than ever.

.jpg)

.jpg)

.jpg)

.jpg)