.png)

HDPE Tee Fitting

Detailed Characteristics

1. Structural Design:

-

The HDPE tee fitting features a classic “T” shape, designed to connect three pipelines — one inlet and two outlets (or vice versa).

-

It is used to split or combine flows, especially in complex pipeline networks.

2. Material Specification:

-

Made from High-Density Polyethylene (HDPE) — a thermoplastic polymer known for:

-

High tensile strength

-

Excellent flexibility

-

Resistance to environmental stress cracking

-

Inertness to a wide range of chemicals

-

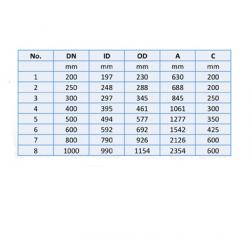

3. Size Availability:

-

Available in a broad range of diameters, from 200 mm up to 1000 mm, making it suitable for medium to large-scale infrastructure projects.

4. Pressure and Impact Resistance:

-

Capable of withstanding high internal pressures.

-

Offers superior impact resistance, even in sub-zero temperatures.

-

Maintains structural integrity in both buried and above-ground installations.

5. Environmental Durability:

-

Resistant to:

-

Corrosion, both chemical and electrochemical

-

UV degradation from prolonged sun exposure

-

Abrasion and rough handling

-

-

Does not rust, rot, or support biological growth such as algae or fungi.

6. Longevity and Maintenance:

-

Designed for a service life of over 50 years, under normal operating conditions.

-

Minimal maintenance requirements thanks to the material's non-reactive properties and leak-proof welding methods.

Expanded Applications

1. Water Supply Systems:

-

Used extensively in municipal waterworks, housing developments, and high-rise buildings.

-

Ideal for branching from a main line to multiple zones (e.g., residential blocks or buildings).

2. Agricultural and Irrigation Projects:

-

Enables water distribution from main lines to field pipelines.

-

Compatible with drip irrigation and sprinkler systems, helping improve water management efficiency.

3. Industrial and Chemical Transport:

-

Suitable for transporting:

-

Aggressive fluids and industrial chemicals

-

Slurries and waste water

-

-

Widely used in factories, processing plants, and chemical parks.

4. Mining and Slurry Applications:

-

Withstands the abrasive nature of materials such as sand, gravel, and ore in mining operations.

-

Can handle high-velocity flow in rugged environments.

5. Wastewater and Drainage Systems:

-

Supports flow redirection in sewerage systems and stormwater drainage.

-

Prevents leaks and contamination due to fusion-welded connections.

6. Compatibility with Jointing Techniques:

-

Supports multiple jointing methods:

-

Butt fusion welding

-

Electrofusion welding

-

Mechanical fittings (if required)

-

-

Ensures strong, seamless, and leak-free connections across the system.

7. Installation Efficiency:

-

Lightweight compared to metal fittings, reducing handling and installation costs.

-

Suitable for installation in remote, rural, or hard-to-reach areas without requiring heavy machinery

.jpg)

.jpg)