.jpg)

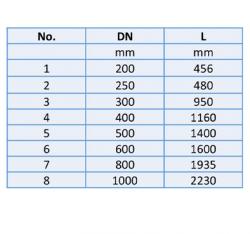

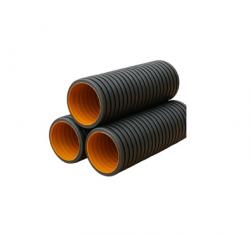

Double Wall Corrugated

APPLICATIONS

• Outstanding characteristics

HDPE double wall corrugated pipes have many advantages in terms of: Durable, high economic, non corrosive.

High density, smooth, flat interior with less friction, good flow regime, the inner and outer walls are extruded plywood structure should be resistant. high pressure and impact strength.

Good chemical resistance, no rust, decay, longevity over 50 years, suitable for acid, nippers, wastewater, organic water (for garbage treatment plants), salt water. Suitable for all regions.

• Superior features

Reduced construction costs, less cost for repair and maintenance of pipelines.

Due to its light weight, it is easy to transport, install and repair, thus shortening the installation time, saving installation time.

Installation of all terrain due to the connection accessories simple, quick operation, compact. It is possible to adjust the length of the pipe to reduce the joint, reduce the amount of breakage, reduce labor costs, thereby reducing the cost of construction.

• Water tightness

The pipes are connected by modern methods.

No leaks and water from the outside.

• Loading, transportation, preservation.

Due to the lightweight tube, it can be easily transported along the groove without the need for lifting equipment.

Pipes can be interlocked during transport, thus saving area. • Store pipes under the roof or in shaded areas in ambient temperatures below 35°C.

ii.Flexible Pipe Characteristics

1. High Flexibility

Can be bent, curved, or twisted easily without cracking or breaking.

Suitable for installation in environments with complex or constrained conditions.

2. Corrosion Resistance

Made from materials such as HDPE, PVC, PPR, or coated metals.

Ideal for use in water, chemical, or gas systems.

3. Lightweight

Easy to transport and install.

No need for heavy machinery for installation.

4. Pressure Resistance

Most flexible pipes are designed to withstand high water pressure.

Pressure capacity depends on the pipe class (e.g., PN6, PN10, PN16...).

5. Long Lifespan (Durability)

Does not crack or break easily even in mechanical environments.

Service life can range from 20 to 50 years, depending on the material.

6. Thermal & Chemical Tolerance

Capable of withstanding hot water or chemicals (e.g., PPR pipes are used for hot water).

Does not deform or lose its properties easily.

7. Cost Efficiency

Generally cheaper than metal pipes and easier to install, making it cost-effective.

Examples of Common Flexible Pipes:

-

HDPE (High-Density Polyethylene)

-

LDPE (Low-Density Polyethylene)

-

PPR (Polypropylene Random Copolymer)

-

Flexible PVC Pipe

-

Corrugated Pipe (e.g., coiled or ribbed flexible pipe)

.jpg)

.jpg)

.jpg)

Double Wall Corrugated

APPLICATIONS

• Outstanding characteristics

HDPE double wall corrugated pipes have many advantages in terms of: Durable, high economic, non corrosive.

High density, smooth, flat interior with less friction, good flow regime, the inner and outer walls are extruded plywood structure should be resistant. high pressure and impact strength.

Good chemical resistance, no rust, decay, longevity over 50 years, suitable for acid, nippers, wastewater, organic water (for garbage treatment plants), salt water. Suitable for all regions.

• Superior features

Reduced construction costs, less cost for repair and maintenance of pipelines.

Due to its light weight, it is easy to transport, install and repair, thus shortening the installation time, saving installation time.

Installation of all terrain due to the connection accessories simple, quick operation, compact. It is possible to adjust the length of the pipe to reduce the joint, reduce the amount of breakage, reduce labor costs, thereby reducing the cost of construction.

• Water tightness

The pipes are connected by modern methods.

No leaks and water from the outside.

• Loading, transportation, preservation.

Due to the lightweight tube, it can be easily transported along the groove without the need for lifting equipment.

Pipes can be interlocked during transport, thus saving area. • Store pipes under the roof or in shaded areas in ambient temperatures below 35°C.

ii.Flexible Pipe Characteristics

1. High Flexibility

Can be bent, curved, or twisted easily without cracking or breaking.

Suitable for installation in environments with complex or constrained conditions.

2. Corrosion Resistance

Made from materials such as HDPE, PVC, PPR, or coated metals.

Ideal for use in water, chemical, or gas systems.

3. Lightweight

Easy to transport and install.

No need for heavy machinery for installation.

4. Pressure Resistance

Most flexible pipes are designed to withstand high water pressure.

Pressure capacity depends on the pipe class (e.g., PN6, PN10, PN16...).

5. Long Lifespan (Durability)

Does not crack or break easily even in mechanical environments.

Service life can range from 20 to 50 years, depending on the material.

6. Thermal & Chemical Tolerance

Capable of withstanding hot water or chemicals (e.g., PPR pipes are used for hot water).

Does not deform or lose its properties easily.

7. Cost Efficiency

Generally cheaper than metal pipes and easier to install, making it cost-effective.

Examples of Common Flexible Pipes:

-

HDPE (High-Density Polyethylene)

-

LDPE (Low-Density Polyethylene)

-

PPR (Polypropylene Random Copolymer)

-

Flexible PVC Pipe

-

Corrugated Pipe (e.g., coiled or ribbed flexible pipe)\

-

.jpg)

.jpg)